How a Dirt Bike Engine Works

If you’re reading this, the odds are pretty good that you are interested in dirt bikes. If that’s the case, then it’s likely you’ve wondered how a dirt bike engine works. Well, wonder no more! This blog post will tell you everything there is to know about the inner workings of a dirt bike engine and what makes them tick.

From ignition timing to compression ratios and so much more, we’ll cover it all right here! So whether you’re just looking for some light reading or if your goal is to be able to rebuild your own dirt bike with nothing but spare parts from Home Depot, then this article has something for you!

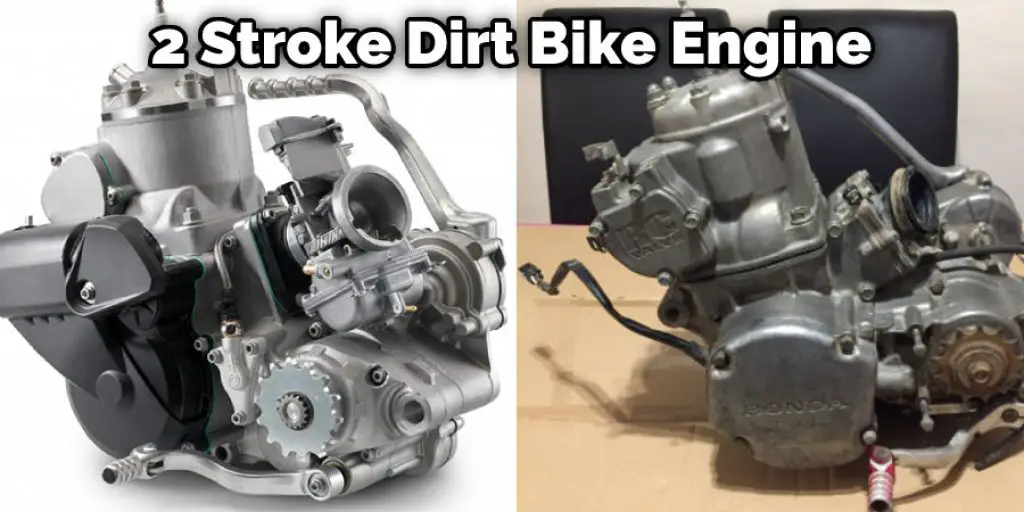

What Kind of Engines Do Dirt Bikes Have?

The most common dirt bike engine types are single-cylinder or four-stroke multi-cylinder (V2, V4, etc.). Of course, most street bikes use a similar engine design as well. But many dirt bikes have four-stroke engines. This is because the combustion process used in a four-stroke engine is more efficient than that of two-stroke engines.

Add to that the fact that four strokes are inherently simpler (with only 2 moving parts: valves and a crankshaft) and dirt bike manufacturers found this kind of engine advantageous in their machines. Since the technology was so well developed, manufacturers had to make modifications that would allow these kinds of engines to operate properly on the race track and still be able to perform at a high level.

Advantages and Disadvantages of a Two-stroke Cycle Engine

Advantages of a Two-Stroke Engine

- The main advantage of a 2-stroke engine is that they are lighter than four-stroke engines. In a two-stroke engine, the crankcase, carburetor, and intake manifold are combined into one part (called a cylinder head). This makes the engine more compact and lighter, which is great for performance and speed.

- Another advantage of a 2-stroke engine is that it has fewer moving parts than a 4-stroke engine. Because there are fewer moving parts in two strokes, this can help prevent mechanical failures from occurring.

- Compared to a 4-stroke engine, 2-strokes engines are easier to start. This is because two-stroke engines fire every revolution rather than every other revolution like four strokes. Also, two-stroke engines don’t need a separate starter motor like 4-stroke engines do so that they can be started easily with an electric starter or by hand.

- The fourth advantage is that they are less expensive to manufacture. This is because there are fewer parts in a two-stroke engine than in a four-stroke engine.

Disadvantages of a Two-Stroke Engine

- The main disadvantage of 2-strokes engines is that they don’t last as long as 4-stroke engines. In addition, they have more moving parts and are more difficult to start; therefore, they need servicing and maintenance more often than 4-strokes.

- Although 2 stroke dirt bike engine may be lighter than 4 strokes when it comes down to the pure physical weight of the bike itself, a two-stroke has much less power than a four-stroke. The reason for this is because two-strokes engines don’t have as much power or torque.

- Because of the extra mechanical parts, they are more expensive to manufacture than 4 strokes and therefore cost more money for the consumer to own one.

- 2-stroke engines release a lot of unburned oil into the air. This can cause smog and contribute to health problems among the people living in big cities.

Advantages and Disadvantages of a Four-Stroke Cycle Engine

Advantages of a Four-Stroke Engine:

- The engine has only one power stroke per crank revolution (one cylinder firing) compared to a two-stroke cycle engine which has two power strokes per revolution (two-cylinder block).

- Allows for a higher compression ratio, and therefore the ability to use heavier fuel.

- The four-stroke cycle has a natural lubricating system, eliminating the need for oil injection or pre-mixing of fuel and oil in two-stroke engines. However, this advantage is negated because the fuel must be mixed with oil to increase lubrication in two-stroke engines.

- Four-stroke motorcycle engines are more efficient than two-strokes, resulting in longer engine life and improvements to fuel economy.

Disadvantages of a Four-Stroke Engine:

- Due to the crankcase used for lubrication, four-stroke engines require more maintenance than two-stroke engines.

- They are heavier and bulkier due to the extra components needed for lubrication, particularly a crankcase.

- It Needs twice the number of crankshaft revolution compared to a two-stroke engine. For example, if you are riding on a 400cc dirt bike, you will have to crank the engine around 800 times (400cc/2) or 400 revolutions using a two-stroke engine to get the same power as provided by a four-stroke engine.

- It is more difficult to achieve similar power output in a four-stroke engine. If you are riding on the same 400cc dirt bike and trying to maintain the same power using a two-stroke motors engine, you will have to get an engine of 800cc or larger for this purpose. Since it is not easy to increase the cubic capacity of a four-stroke engine, it will be much cheaper to go for an 800cc two-stroke bike.

How Two-Stroke Cycle Engine Works?

The 2-stroke engine is designed with a crankcase, piston, connecting rod, induction pipe (suction chamber), power cylinder, exhaust pipe (exhaust chamber), and valves controlled by overhead camshafts. First of all, an air pressure suction process is done into the crankcase, and then a fuel mixture is injected, followed by ignition of the mixture. After that, an induction stroke and power cycles begin at once.

In the induction stroke, the compressed air-fuel mix gets into the power cylinder volume through the induction pipe (suction chamber). In this case, fuel is mixed with air in ideal proportion by a carburetor of a 2-stroke engine. Then, with a piston pulse moving up, the air-fuel mixture gets into the cylinder chamber as well, and then this mixture is compressed maximally by the closing of intake and exhaust valves.

Then, in the power stroke, ignition takes place, and following combustion of the fuel in the air-fuel mixture, the burnt gas in the power cylinder expands and pushes down the piston. After that, the exhaust valve opens for releasing exhaust gas, while the intake valve closes for the intake air-fuel mixture into a crankcase again.

How Four-Stroke Cycle Engine Works?

A four-stroke engine completes one cycle when it makes two complete rotations. A cylinder has four strokes: intake, compression, combustion, and exhaust. The downward movement of the piston from TDC to BDC is the intake stroke. When the piston travels from BDC to TDC, it moves for compression. The fuel is present within the chamber gets ignited and thus begins combustion. During this process, some of the energy contained in the fuel is used to drive crankshaft movement.

Also, during this process, a mixture of air and fuel is compressed. As a result, the pressure within the combustion stroke chamber increases to a level when the fuel gets ignited and burnt. The downward movement of the piston during its return from TDC to BDC is known as intake stroke or scavenging process that pushes out the waste gases, which had been generated during combustion.

In a four-stroke engine, there are only four events of combustion engines. These are:

- Intake Stroke (Advance), where fuel and air get mixed at the beginning of compression stroke during crankshaft rotation.

- Compression Stroke (Power), where fuel and air get burnt on compression stroke when the piston is at BDC. A perfect mixture of fuel and air, i.e., 14.5 to 1, is attained at the top of the compression stroke.

- Power Stroke (Ignition), where an ignition or spark plug produces hot gasses ignited by fuel tank present and burnt inside the cylinder during piston movement from TDC to BDC.

- Exhaust Stroke (Release) where connecting rod using a crank throws out exhaust gases through an exhaust valve.

Two-Stroke Cycle Engine vs. Four-Stroke Cycle Engine

- A two-stroke engine is powered by a power stroke only. A four-stroke engine is powered by an intake, compression, expansion, and exhaust stroke.

- A two-stroke dirt bike engine uses only the bottom of its piston to scavenge air, fuel, and exhaust out of the cylinder. A four-stroke engine uses both the top and bottom piston for these functions.

- In a four-stroke engine, the intake stroke is forced, while the rest are volumetric (relaxed). In a two-stroke engine, the intake stroke happens naturally with the expansion of exhaust gases.

- A four-stroke engine fires a new charge on each power stroke, while a two-stroke charges only once. This is why you need to mix your engine oil with your gas in 4 strokes and do not mix them for 2 strokes.

- A four-stroke engine will scavenge air and fuel from the intake, which is why you can “choke” it at low RPM. In a 2 stroke, this is not possible due to the method of combustion (expansion)

- The exhaust systems on a 4 stroke are normally more complex than on a two-stroke because of needing to be separate from the intake.

- The operation of a two-stroke is the opposite of a four-stroke in many ways. For example, a four-stroke has intake port, compression, , while a 2 stroke only has an intake and expansion stroke.

- When the piston moves down on the power stroke for 4 strokes, it forces fuel/air into the cylinder, while it’s going down on the expansion stroke of a 2 stroke.

How Do Pistons Move in Four Stroke Engine?

A Inside the cylinder of an engine, there is a piston. The movement of this piston is what helps keep everything moving and working together to make sure that it pumps all the gas out and allows more gas to come into the different openings. When you have your finger over one of these openings, you will feel a strong suction on your finger. This is the pump sucking in all of the air from that one opening and forcing it out into a different opening.

When you remove your finger from any of these openings, you will see how quickly gas comes spraying out of them. This is because all four strokes are “cracking” open and closing those different openings and allowing for a more efficient way to get all of the gas out and more in. It doesn’t matter if they are moving upwards, downwards, or sideways since this makes them work so efficiently.

Conclusion

The engine of a dirt bike is the most important part. If you don’t know how it works, then your dirt bike will not work properly. In this blog post, we’ll break down the key components of a dirt bike’s engine and talk about what they do to create power for both on-road and off-road driving conditions.

After reading this article, we hope that you have a better understanding of how a dirt bike engine works so that when maintenance needs arise or any other questions come up in regards to your motorbike, you’re prepared!